Lars Lovik AB

Kållandsgatan 20

531 30 Lidköping - SWEDEN

+46 (0)510 918 81

lovik@bulkteknik.se

Wear Parts

SPECIALIST IN INTERMEDIATE BEARINGS FOR SCREW CONVEYORS

The Lovik type of intermediate bearings is the result of more than 40 years of experience in screw conveyors within the cement industry.

The cement industry requested an intermediate bearing which was reliable, easy to exchange and had a very long life of operation and finally a moderate price.

The answer was the Lovik intermediate bearing with easily exchangeable standardized tungsten carbide wear linings,

The wear linings are easily exchanged without removing the shaft, which means that downtime is minimum for bearing renewal, as only wear linings have to be replaced.

Designed for handling powdery cargos such as: Cement, Fly ash, Grinded slag (GGBS), Limestone powder, Raw meal for example,

Advantages:

-

Outstanding performance

-

No lubrication needed for screw elevators handling cement

-

Both sealed and non-sealed bearing types available

-

Easy to adapt the shaft and holder to fit any screw conveyor

-

Wear lining are always standard stock parts

-

Easily exchangeable wear parts for minimum downtime

Manufacturing

The wear linings are of top quality tungsten carbide and the bearing housings and bearing holders manufactured of cast iron to receive excellent performance.

The bearings are manufactured using the latest CNC machines and then diamond grinded for highest finish and tolerances. All parts are manufactured in Sweden.

Models

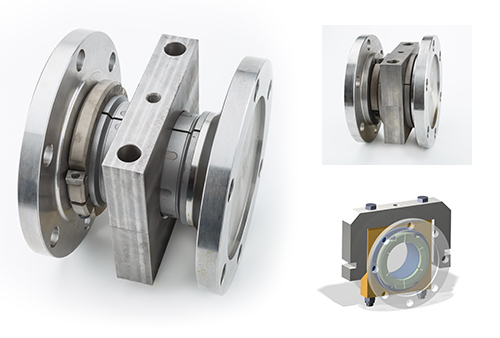

Hanger bearings for horizontal screw conveyors, type LMLH and HSC/HML in all sizes.

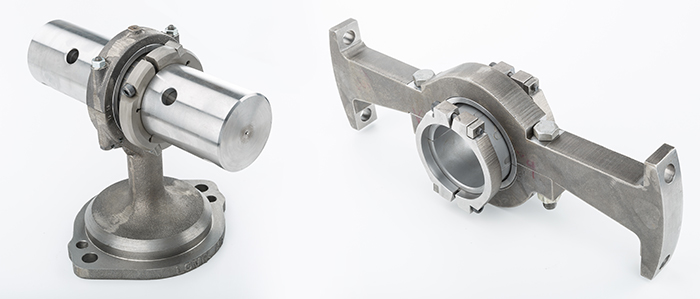

Intermediate bearing parts for screw elevators (vertical screw conveyors) such as bearing holders, shafts, wear sleeves, wear rings and clamping rings. For both type LSE and VSC in seald and non seald versions. All sizes VSC300, VSC400, VSC500, VSC600 and VSC700.

« Back